Inside the Door: Why Core Construction Matters in Interior Door Design

When choosing an interior door, most people focus on its appearance: laminate finishes, wood grains, or colour tones. But beneath the surface lies a detail that has a far greater influence on performance: the door’s core construction. Whether you’re exploring contemporary wood door design, traditional teak wood door designs, or sleek laminated door design styles, the internal structure of the door determines how it functions, lasts, and fits into your living or working space.

From acoustic insulation and durability to weight and hardware compatibility, the core is the unsung hero of every door. Understanding what lies beneath can help you make better choices, not just for aesthetics, but also for how the door behaves in daily use.

Table of Contents

ToggleThe Core of the Matter: Why Interior Door Construction Counts

Interior doors endure a lot, including frequent opening and closing, exposure to humidity, temperature changes, and the constant pull of hinges and hardware. Traditional solid wood doors, although elegant, often fall short in consistency and stability, especially in controlled environments like modern homes, offices, or hotels.

This is where engineered doors redefine reliability. Brands like Mikasa Doors & Frames use advanced interior door design principles that focus on optimising core construction for performance, not just appearance. A well-engineered door delivers:

- Better dimensional stability

- Uniform density for seamless finishes

- Lighter weight for smooth operation

- Superior sound insulation for privacy

The core makes all the difference, especially when paired with modern materials such as high-pressure laminates, lacquered finishes, or decorative veneers. With evolving architectural needs and interior layouts, choosing the right door core is no longer optional, it’s essential.

Related: Enhance Your Interiors with Stunning Wood Door Designs by Mikasa

What Goes Into a Door Leaf? A Quick Anatomy

A well-constructed door is more than just a slab of wood. At Mikasa, every door leaf is a precision-engineered composite designed for strength, longevity, and seamless design integration. Here’s what typically makes up a high-performance interior door:

1. Core

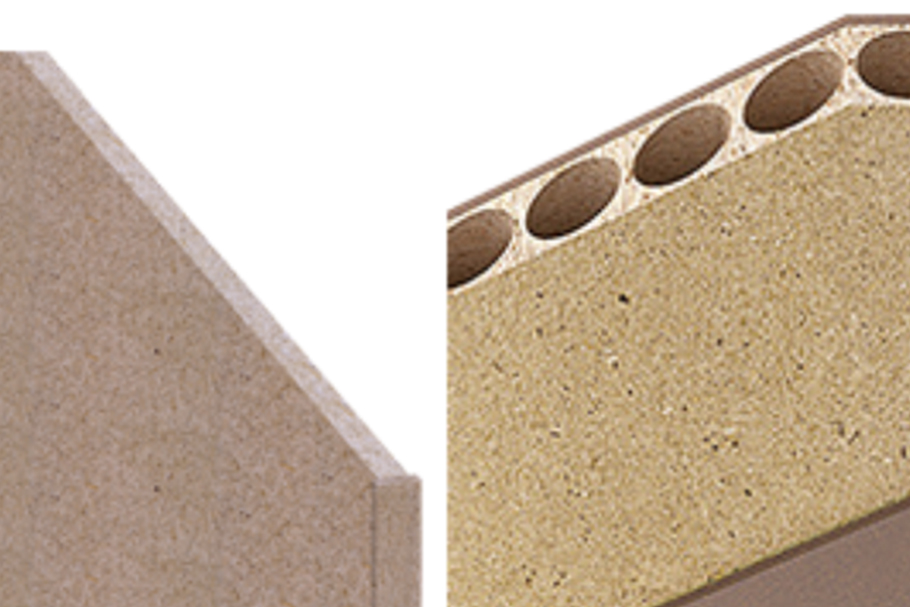

The heart of the door. Mikasa offers two main types:

- Tubular Core: Features uniformly spaced cylindrical voids that reduce weight without compromising strength. This core type offers excellent dimensional stability and acoustic insulation. Ideal for upscale residential and commercial interiors.

- Solid Particle Core: Made from high-density engineered wood particles pressed together for a denser, heavier structure. Offers enhanced impact resistance and better anchoring for hardware. Suitable for high-traffic areas or where robustness is a priority.

Both cores exceed key performance metrics in terms of screw-holding strength, static torsion, and resistance against jarring and vibration.

2. Stiles and Rails

These are the solid sections around the perimeter of the door leaf, made from high-quality hardwood or softwood. They provide structural support and house hinges, locks, and handles. Mikasa uses laminated veneer lumber (LVL) stile and rail to ensure strength and bonding integrity.

3. Adhesive System

It’s not just about the layers; it’s about how well they stick together. Mikasa uses proprietary adhesives that are tested for moisture resistance and bonding strength. This ensures long-term durability even in tough environments like bathrooms or kitchens.

4. Surface Material

The outer layer can be selected based on function and design, ranging from high-pressure laminated door design options to teak wood door designs with wood veneers for a more traditional, warm look. Mikasa offers a range of finishes that are resistant to scratches, stains, and fading.

5. Edge Banding

Edge protection is vital, especially for flush and laminated doors. Mikasa uses precision-machined edge banding that matches the finish and enhances both visual uniformity and surface protection.

Together, these components create a door that’s not only visually appealing but structurally sound, acoustically quiet, and highly durable.

Related: 3 Trending Home Door Design Ideas for a Stylish Welcome

Comparing Tubular vs Solid Particle Core: Which One’s Right for You?

Choosing between tubular and solid particle core construction depends on your specific project needs, whether it’s a luxury home, commercial office, hospitality space, or healthcare facility. Here’s a breakdown to help you decide:

|

Feature |

Tubular Core |

Solid Particle Core |

|

Weight |

Lighter, easier to handle |

Heavier, more substantial |

|

Sound Insulation |

Excellent due to air pockets |

Good, but slightly lower than tubular |

|

Hardware Fixing |

Reliable for standard use |

Exceptional screw holding strength |

|

Durability |

Stable, warp-resistant |

Superior impact resistance |

|

Application |

Ideal for premium residences, hotels, and office cabins |

Best for high-traffic or institutional areas |

|

Fire Rating |

Compatible with fire-rated constructions |

Also suitable with fire-resistant door specs |

|

Cost |

Slightly higher due to precision |

More cost-effective in heavy-duty builds |

Use Cases

- Tubular Core: Perfect for homeowners or architects who prioritise performance, weight management, and noise reduction. Its uniform density and moisture resistance make it excellent for climate-controlled interiors.

- Solid Particle Core: The preferred choice for applications where door abuse is common, such as public buildings, hospitals, or schools. Its dense construction resists dents, boosts lifespan, and holds heavier hardware without issues.

Both core types meet global performance benchmarks, and when paired with Mikasa’s finishing options, like laminated door designs or wooden veneers, they offer unmatched versatility.

Related: Top Wooden Door Designs for Creating a Warm, Welcoming Home

Surface Finishes That Elevate Every Design

The core may determine a door’s strength, but the finish defines its personality. Mikasa Doors offers a curated selection of surface materials that merge durability with design freedom, making each wood door design both functional and striking.

Laminated Door Design

For homeowners and designers seeking a modern, low-maintenance finish, laminates are a smart choice. Mikasa’s laminate offerings are:

- Scratch and stain-resistant

- Available in a variety of textures: matte, gloss, fabric, woodgrain, and more

- Easy to clean, making them ideal for high-usage interior spaces

- Offered in both solid colours and realistic wood finishes

Whether you’re planning a minimalist flat-panel look or a bold contemporary statement, a laminated door design offers flexibility without sacrificing performance.

Teak Veneer and Other Natural Wood Options

For those who prefer timeless charm, teak wood door designs bring natural grain and warmth into interior settings. Mikasa offers real-wood veneers, including steam beech and teak, that deliver:

- A rich, organic finish

- Unique grain patterns (no two doors look the same)

- Compatibility with lacquer or PU coatings for enhanced durability

- A luxurious feel suited for formal and premium living spaces

Paint Finishes

For projects that demand customisation and colour coordination, Mikasa doors can be factory-finished in any paint colour of your choice.

- Available in any RAL or international standard shade

- Supplied with a smooth or textured finish as required

- Offers excellent colour retention, smoothness, and surface uniformity

- Suitable for both contemporary and classical interior themes

Painted doors are especially useful in projects where branding colours, accent shades, or high-impact design statements are key.

Customisation and Design Consistency

Mikasa ensures design harmony across projects by allowing customers to:

- Match door and door frame design

- Align finishes with wall panels or furniture laminates

- Choose from different groove patterns, inlays, and hardware colours

With options for fire-rated finishes, antibacterial coatings, and seamless edge banding, the surface design of your door can be both a visual and functional asset.

Related: 4 Ways To Make Your Interior Door Design a Centrepiece of Your Space

Choosing the Right Core and Finish for Your Interior Doors

Selecting the right interior door isn’t just about matching your décor; it’s about aligning aesthetics, function, and longevity. If your focus is weight reduction and acoustic comfort, a tubular core offers excellent balance. Need higher impact resistance or fire-rated performance? Opt for a solid particle core. For shared living or healthcare spaces, surfaces with antibacterial properties are a smart addition.

When it comes to finishes, choose laminated door designs for high-traffic zones like kitchens, corridors, or offices. If the goal is luxury and warmth, especially in lounges, bedrooms, or formal areas, teak wood door designs or other real wood veneers lend authenticity.

Consider your door frame too. Mikasa’s matching door frame designs are not only moisture resistant and structurally sound but also complete the visual symmetry of your space.

With a clear understanding of core technology and surface finishes, you’re better equipped to select doors that blend beautifully with your interiors, while performing reliably over time.

About Mikasa Doors

Mikasa Doors is a leading name in engineered wooden doors, known for its precision manufacturing, advanced core technology, and world-class finishes. Every door is built to meet performance and design expectations in modern Indian interiors. Looking to upgrade your interiors with smart, stylish, and durable wooden doors? Explore our range today or get in touch with our experts to find the ideal match for your project. Call 1800-833-0004 or email info@mikasadoors.com to discuss your requirements and find the perfect doors for your space today! You can also visit our contact form, and we will get back to you at the earliest.

Frequently Asked Questions

1. What is the difference between a tubular core and a solid particle core in wooden doors?

Tubular core features uniformly spaced cylindrical cavities for weight reduction and sound insulation, while solid particle core is denser and offers higher impact resistance and better screw-holding strength.

2. Are engineered wooden doors more durable than traditional solid wood doors?

Yes. Mikasa’s engineered wooden doors are dimensionally stable and less prone to warping or cracking compared to solid wood alternatives.

3. What type of wood is used in Mikasa’s teak wood door designs?

Mikasa offers genuine teak veneers or teak-inspired laminate finishes over engineered cores, ensuring both beauty and performance in every door.

4. Is laminated door design suitable for interior door applications?

Absolutely. Laminated doors are ideal for interiors as they are scratch-resistant, easy to maintain, and available in a wide variety of colours, patterns, and textures.

5. What makes Mikasa’s door frame design different from conventional frames?

Mikasa’s engineered door frames are moisture-resistant, structurally balanced, and designed to match the door leaf perfectly, ensuring both aesthetic and functional harmony.

6. Do Mikasa doors come with fire-rated options?

Mikasa offers fire-rated doors with certified fire-resistant core constructions and intumescent seal compatibility for added safety in commercial and residential buildings.

7. How does door core selection affect sound insulation?

Tubular cores offer excellent sound reduction due to their internal structure. Solid cores also insulate sound well but are typically chosen for their strength and density.

8. Can I customise the size, finish, or groove patterns of a Mikasa wooden door?

Mikasa allows extensive customisation of wood door designs including size, surface finish (laminate or veneer), grooves, inlays, and hardware.

9. Where can I view or download the Mikasa wood door design catalogue?

You can explore the full range of wood door designs, laminated options, and technical specifications here.

A Comprehensive Guide to Mikasa’s Dura (Durability) Doors

The first impression is the last impression, and interior designs are no exception to the rule. Door

Looking to Buy Engineered Wood Doors? Learn about the Core Options

Engineered wood doors, a remarkable alternative to wooden doors, consist of a solid core and real wo

Transforming Spaces with Elegance: The Mikasa Doors Experience

In the realm of architectural design, the choice of a door transcends its basic function of entry an